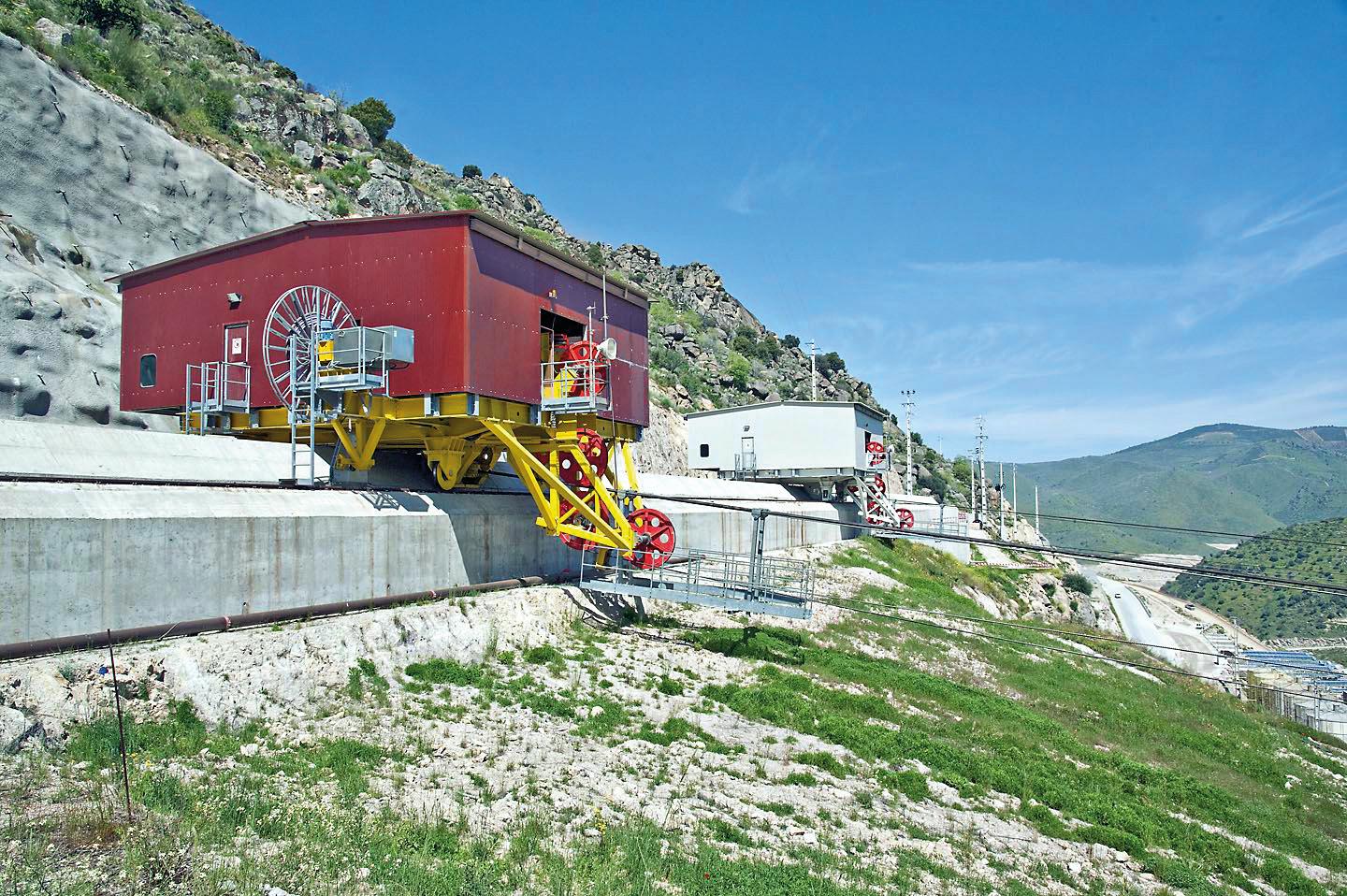

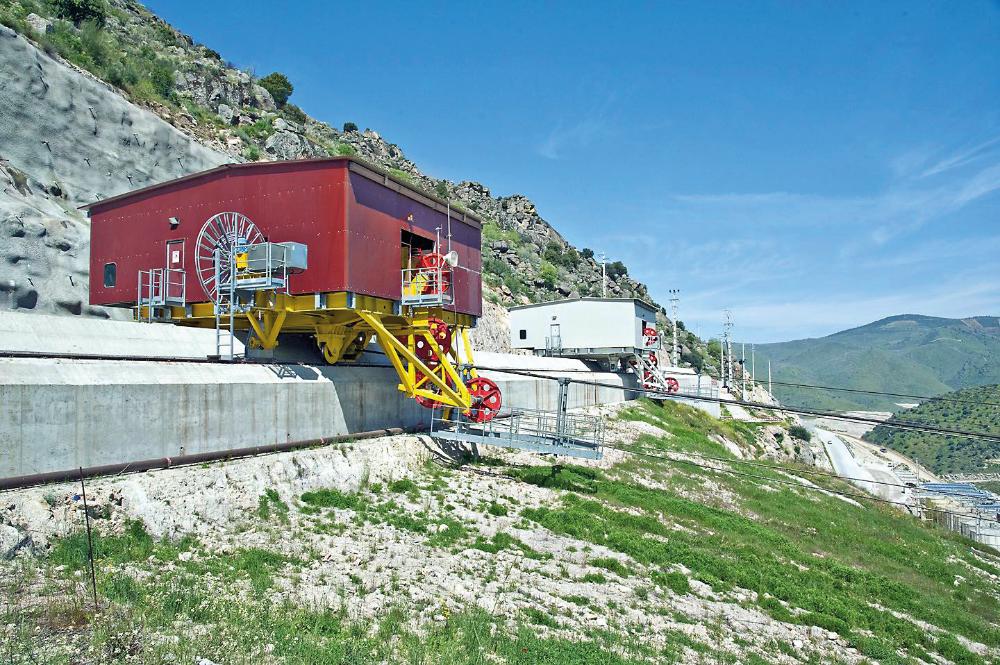

Characteristics of the Agudio Cablecrane

up to

up to

up to

up to

up to

Speed

Agudio cablecranes are the only ones on the market that can reach such high working speeds (8 m/s in translation and 4 m/s in lifting), thanks to patented slack carriers that always keep the ropes in the correct position.

Tandem transport

Two Agudio cablecranes can work in tandem to achieve a payload of 70 tons. A specific control system ensures the automatic operation preventing errors and reducing transport times.

Energy recovery

Agudio cablecranes are equipped with asynchronous AC motors controlled by LEITDRIVE inverters complete with AFE (Active Front End) filters. Thanks to this architecture, during the phases in which the cablecrane generates energy, it is possible to feed the construction site's electrical network.

Stability and performance

The Agudio twin track rope design gives high stability to the cablecrane even in strong wind conditions. This stability, combined with the control of the ropes done with patented slack carriers, guarantees unrivalled performance.